Big Bag Opening Station

By lifting the ton bag to the material inlet, the large bag opening station manually opens the rope at the discharge port of the ton bag. In addition, a beating device is used to make the powder materials in the ton bag fall into the buffer material tank by gravity, and then they are put into the reactor or transported to the next treatment equipment through the connection.

In order to solve the impact of dust flying on the environment and reduce the heavy physical labor of operators, modern enterprises gradually replace the traditional manual bag opening system with mechanical bag opening system. The system not only effectively protects the production environment and reduces the labor intensity, but also improves the production efficiency. It solves the problem of caking and difficult discharging due to moisture absorption in the process of opening large bags.

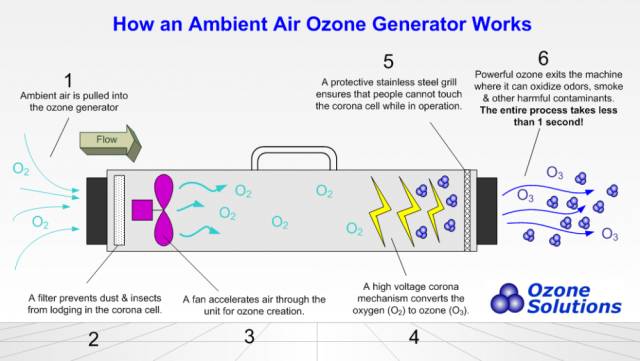

Main working principle:

The system is composed of lifting hanger, bag beating device, pneumatic bag clamping device, buffer tank weighing, screw conveying and discharging pipe. The large bag opening station is used for discharging bagged materials, which is semiautomatic operation. The big bag is lifted by electric hoist. The bag rope of the package bag is hung on the steel support. The hoist is manually controlled to lift and walk. It runs along the walking guide rail to the top of the unloading area and makes the big bag in the unloading position. Press the button. When the clamping cylinder rises, the operator will pull the discharge port of the bag to the inner ring of the bag gripper, press the clamping button, the clamping cylinder will descend, and the bag opening will be clamped by pressing the inner ring of the bag clamping device through the sealing ring. At this time, the operator opens the rope at the discharge port of the ton bag, and the material starts to unload through. There is no dust leakage during the unloading process, and the material starts to unload along the pipeline under the action of gravity. During the unloading process, in order to make the materials flow smoothly in the packaging bags and pipes, the bag beating device is added to loosen the materials. The materials fall into the buffer tank after beating. And evenly transported by the screw to the discharge pipe, and finally to the equipment designated by the customer. After unloading, the bag clamping device opens the bag clamping button, the bag press rises, and the electric hoist is manually operated to lift the empty bag.

Main features of a Bag Opening Station:

• The bag opening station is simple in structure and easy to operate;

• The flapping device can ensure the smooth discharge of materials from large bags;

• The crusher breaks the caking in the process of opening bags to ensure the smooth progress of the next process;

• The magnetic separator can remove the metal foreign matters in the big bag;

• Fully automatic operation, improve production efficiency and reduce labor intensity;

• Closed open bag can eliminate dust flying, improve working environment and reduce production cost;

• Opening bag, beating, crushing, magnetic separation integration design, compact structure, easy to operate;

• Pneumatic or electric control mode can be provided to realize remote monitoring;

• Applicable conditions: large bag packing materials with poor fluidity, easy moisture absorption and caking materials.