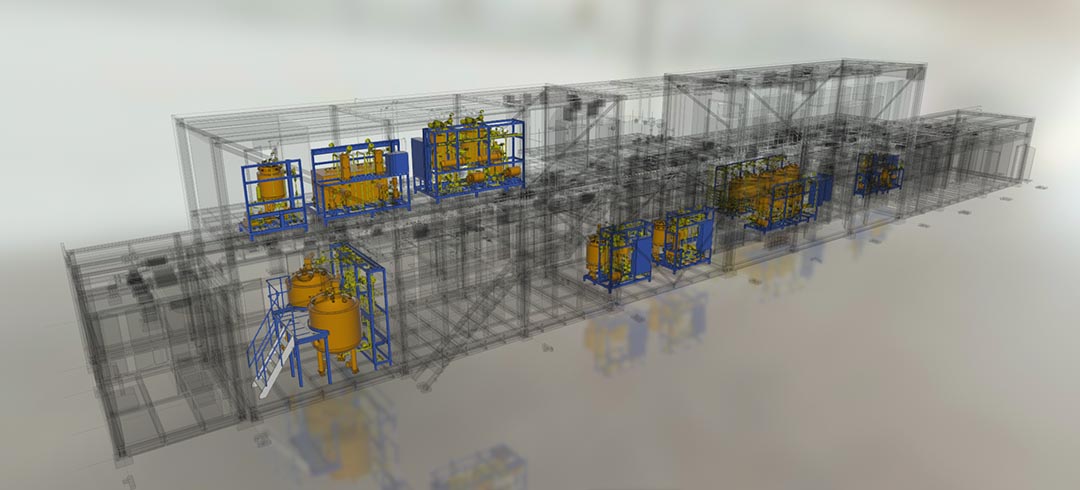

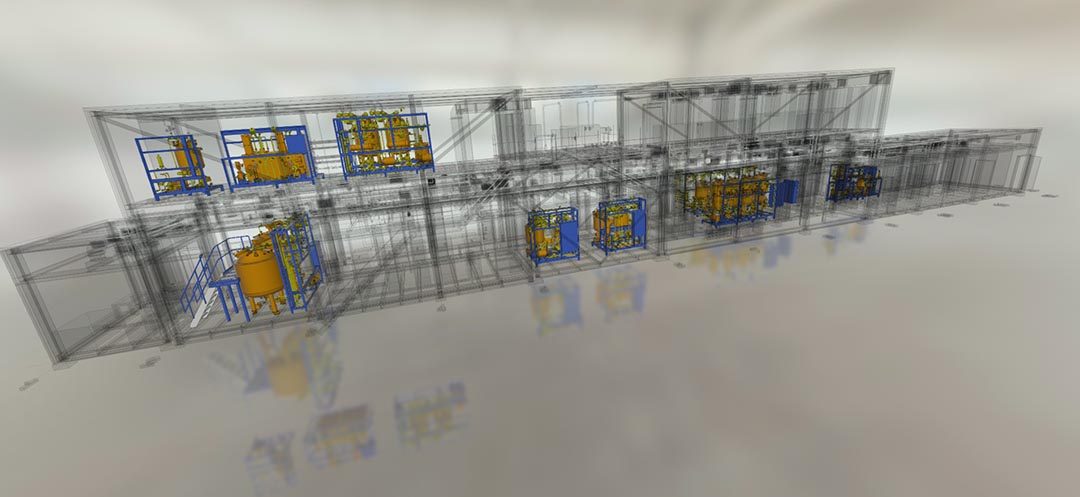

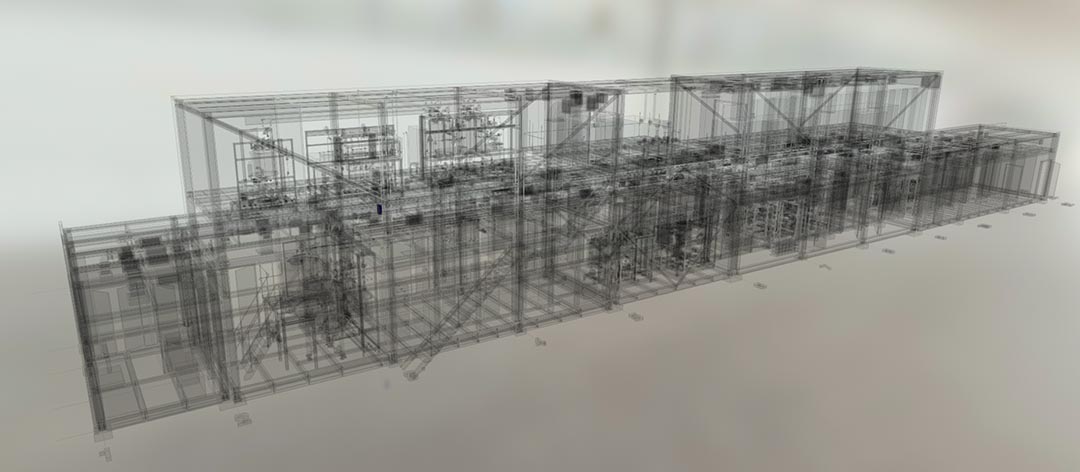

Blood Plasma Fractionation Plant

SYNCS together with alliance C&S Process designed, manufactured and commissioned a complete plant for blood plasma fractionation. It was a turn key solution with delivery term of EPC including the process equipment, control system, hygienic and clean rooms, HVAC, building architecture, structures, utilities, drainage, surveillance system and ground foundation.

SYNCS provided the full detailed design, fabrication, logistics, site construction, commissioning and validation services for the full blood plasma fractionation plant.

The blood plasma fractionation including: viral inactivation workshop, flexible separation and purification workshops, workshop for in-place decontamination of separation equipment, buffer preparation, CIP, in-place sterilization, automation, Nano-filtration sensor module.

Scope of Supply in Equipments

• Frozen plasma dissolution

• Fractionation for Albumin and Globulin

• Buffer preparation

• Albumin UF purification and Pasteurization

• IVIG ETOH

• IVIG Chromo

• IMIG

• Prothrombin Complex (PCC) adsorption, solvent detergent (SD) treatment

• Fibrinogen SD treatment

• Factor VIII SD treatment

• CIP + TCU

Scope Matrix

Benefits of Full Modular Plant:

Schedule - Shorten

• Plant construction and Site Construction progress simultaneously

• Reduced Design Time

• Reduced Overall Project Schedule

• Normally ONE MONTH for Site Installation

Quality - Ensured

• In House Fabrication

• Controlled Environment

• Highly Skilled Workforce

• High Standard QA System

• Continuous Improvement via repetitive executions

• FAT for whole Plant

HSE Conduct - Improved

• Eliminate Risks and Hazardous at Site

• Reduced Construction Setting up Time

• Minimised Impact to the Environment

Client Efforts - Minimised

• Less Interfaces

• Single Point of Responsibility, One Stop Solution

• Fixed execution model for world wide application

• Use available expertise to consider on behalf of the client

Cost - Reduced

• Minimised Client Management Cost

• Avoid Scope Missing/Overlapping and Waste

• Reduced cost from reduced time for Design and Construction

• Utilised Low Labour Cost

• Early production generates early launch to market

• Modular Plant is RELOCATABLE, Increase Asset Life Cycle Value