Color Steel Plate Construction Plan for A Clean Workshop

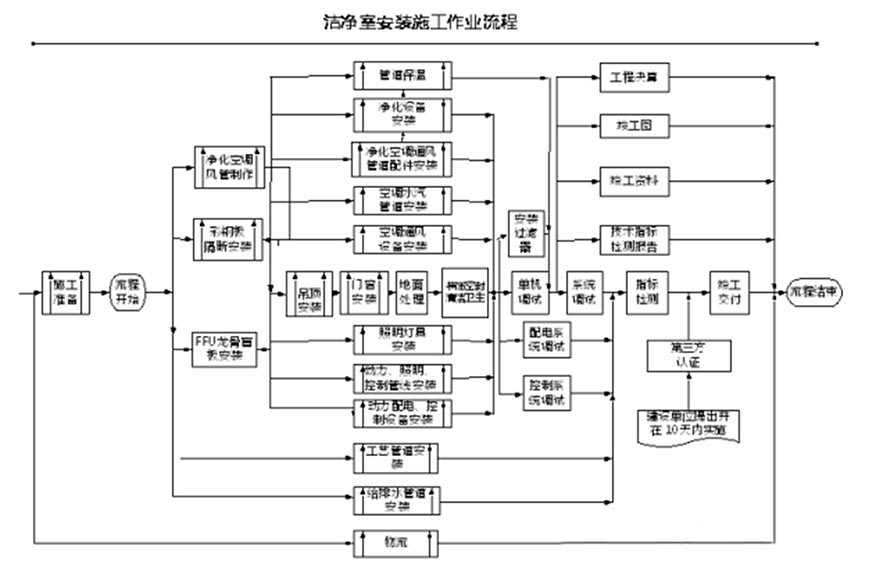

1. Clean room decoration construction process

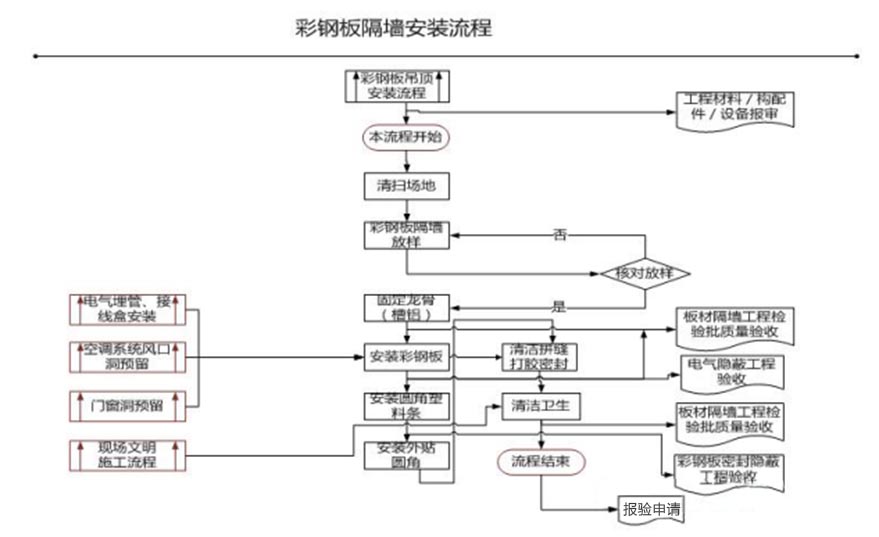

2. Installation process of color steel plate partition wall

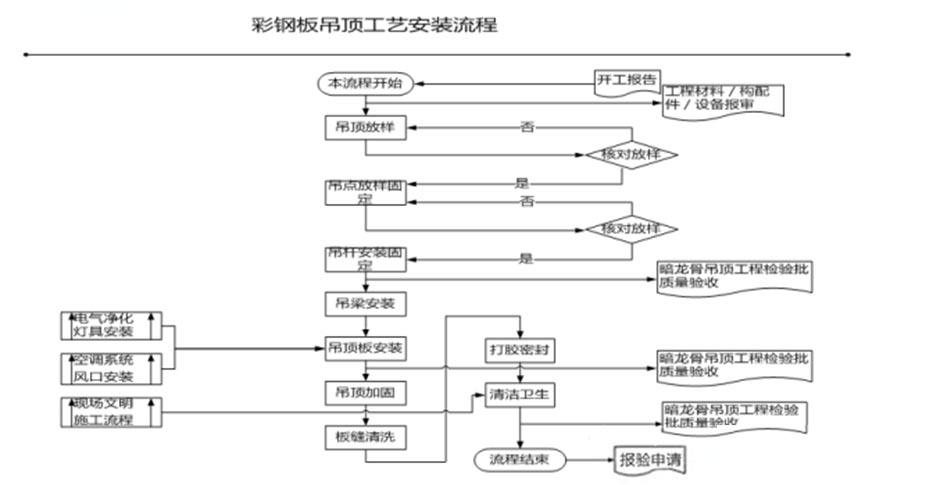

3. Color steel plate ceiling installation process

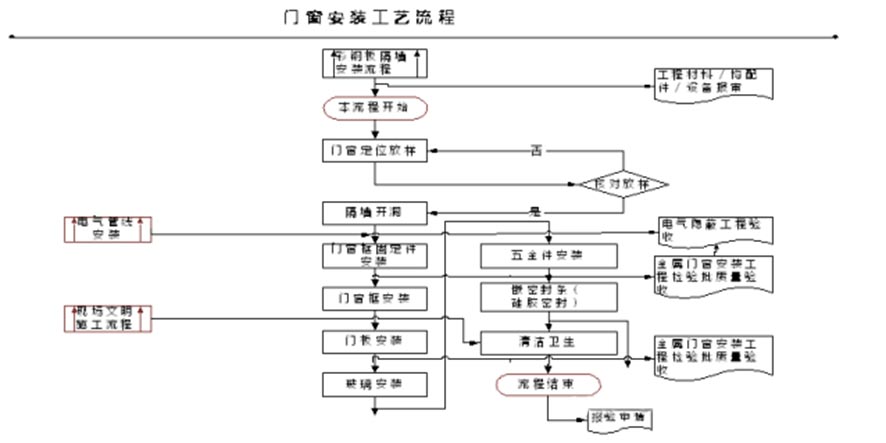

4. Clean room door and window installation process

1. Purification project construction plan

1.1. Building decoration construction plan

1.1.1. Basic requirements before purification and decoration project construction

(1) Civil structure engineering construction is basically completed, and the purification and decoration project work site has no major vibration and noise other sub-project construction operation.

(2) The interior wall plastering project is completed, the concrete floor project construction is completed, the exterior wall door and window project is completed, and the purification and decoration work site requires preliminary flow of people and logistics control.

(3) Other sub-projects inside the suspended ceiling have basically been completed, and various inspections and tests have been completed. The unfinished construction in the suspended ceiling is required to not produce a significant load on the suspended ceiling.

(4) Process equipment with larger internal volume and quality in the purification room is installed in place.

(5) The construction work surface requires sufficient space for the transportation of purification and decoration materials, the movement of construction scaffolding, and the safe supply of construction electricity.

1.1.2. Applicable specifications

(1) "Code for Construction Quality of Building Decoration Engineering" (GB51201-2001)

(2) "Uniform Standard for Construction Quality Acceptance of Building Engineering" (GB50300-2001)

(3) "Code for Clean Plant Design" (GB50073) -2001)

(4) "Code for Construction and Acceptance of Clean Room" (JGJ71-90)

(5) "Code for Filing and Arrangement of Construction Project Documents" (GB/T50328-2002)

(6) "Uniform Standard for Construction Quality Acceptance of Construction Engineering" ( GB50300-2001)

(7) "Code for Construction Quality of Building Decoration Engineering" (GB51201-2001)

(8) "Uniform Standard for Construction Quality Acceptance of Building Engineering" (GB50300-2001)

(9) "Code for Design of Clean Workshop" (GB50073-2001)

(10) "Code for Construction and Acceptance of Clean Room" (JGJ71-90)

(11) "Code for Filing and Arrangement of Construction Project Documents" (GB/T50328-2002)

(12) "Uniform Standard for Construction Quality Acceptance of Construction Engineering" (GB50300-2001)

1.1 3. Color steel plate construction process

Indoor cleaning and wire laying; installation of booms, hanging beams, and roof installation; fixed trough and wall installation; installation of booms, installation of FFU hanger keel, heavy-load blind installation; door and window installation; Install R fillet; wipe board, clean, glue, initial inspection, rectification; clean, complete acceptance.

1.1.3.1. Construction points

The installation of clean enclosure structure is to install the various main pipes in the technical interlayer, and then correct Perform a thorough cleaning of the indoor floor wall and space to ensure that there is no dust. During the construction process, arrange special personnel to clean and clean the construction parts and the site, so as to "clean up the site".

(1) Familiarize yourself before construction The secondary design drawing, complete the site survey, and know the error of the civil construction room. The fixing of the connecting parts such as the hanging and the main structure and the ground should be carried out in strict accordance with the requirements of the secondary design surface.

(2) The civil construction ground and wall The unevenness of the surface should not be greater than 0.1%, and the corners of the wall should be connected vertically. In order to prevent the accumulated error from causing the wall panel to tilt and twist, the verticality deviation of the wall panel should not be more than 0.2%.

(3) The ceiling should be arched according to the width of the room. Keep the suspended ceiling flat during use after being loaded. The surrounding area of the suspended ceiling should be tightly connected with the wall, and the protective film on the surface of the board must not be torn off during the installation. It is forbidden to hit and step on the pedal surface.

(4) The surface layer material needs to be pasted, The surface and groove of the embedded sealant must be strictly cleaned to remove impurities and oil to prevent dust accumulation.

(5) All installation gaps of the eclosure structure must be sealed with silica gel. The embedded sealant should Straight, smooth, without discontinuity, exposure, burrs, etc. The temperature of the environment for gluing should be above 0℃.

(6) Sealing of the gap of the swing door: In the case of frequent opening and closing of the door leaf, except for some In order to avoid heavy equipment and other transportation, the sealing strips are all set on the door leaf. Generally, in order to avoid touching, stepping on or hitting the sealing strips, It can be affected by pedestrians and transportation. Most small sections with a length and width of only a few millimeters are formed into elastic airtight strips, laid on the concealed grooves of the door, and then pressed tightly by closing the door leaf. The sealing strip should be laid continuously along the periphery of the movable gap, so as to form a ring of closed tooth seal line after the door is closed. If the sealing strips are set at the door and door leaf respectively, it must be noted that the two are well connected to minimize the gap between the sealing strips in the door seam.

(7) Pipeline: When the pipe passes through the enclosure structure, it must first have a good fixed structure, and it cannot be shaken and displaced during use to ensure the effect of the sealing measures. The installation and positioning must be organically combined with the sealing treatment. Therefore, a positioning frame is attached to the periphery of each hole opened in the metal wall. The reinforcement of the large-size air pipe should prevent back and forth and left and right movement. Put glue or rubber sponge in the gap between the pipe wall and the metal wall, and then treat it with sealant.

1.1.3.2. Quality requirements

(1) For the materials used in the purification and decoration project, other components should meet the design requirements; the self-purchased parts without design requirements should meet the high quality and ministerial standards. For metal siding, there should be a warranty certificate, performance test report, and certificate of conformity.

(2) Before purification and decoration, the indoor space must be thoroughly cleaned until there is no dust. The metal siding and accessories should be stored in a clean environment and placed flat on the moisture-proof film to prevent deformation. Wall panels and accessories should be unpacked in a clean environment. Unqualified or damaged products shall not be installed.

(3) The metal siding partition wall should be installed smoothly, and the board seam should be vertical and tight. The fixed and hanging parts of the suspended ceiling can only be connected to the main structure, and cannot be cross-mixed with equipment and pipeline supports. The surface of the siding and ceiling should be smooth and flat, free of dust, dust, corrosion resistance, impact resistance and easy to clean.

(4) The yin and yang corners of the floor and wall in the clean room are rounded with aluminum alloy with R=50mm and sealed with silicon sealant. R The rounded corners must be installed straight and tightly connected.

(5) All sealed windows, clean doors and partition gaps need to be sealed with silica gel.

(6) Strictly implement the construction acceptance specifications and quality assessment standards promulgated by the state for purification and decoration projects, and do a good job of acceptance and records of various concealed projects.